Processinstrument

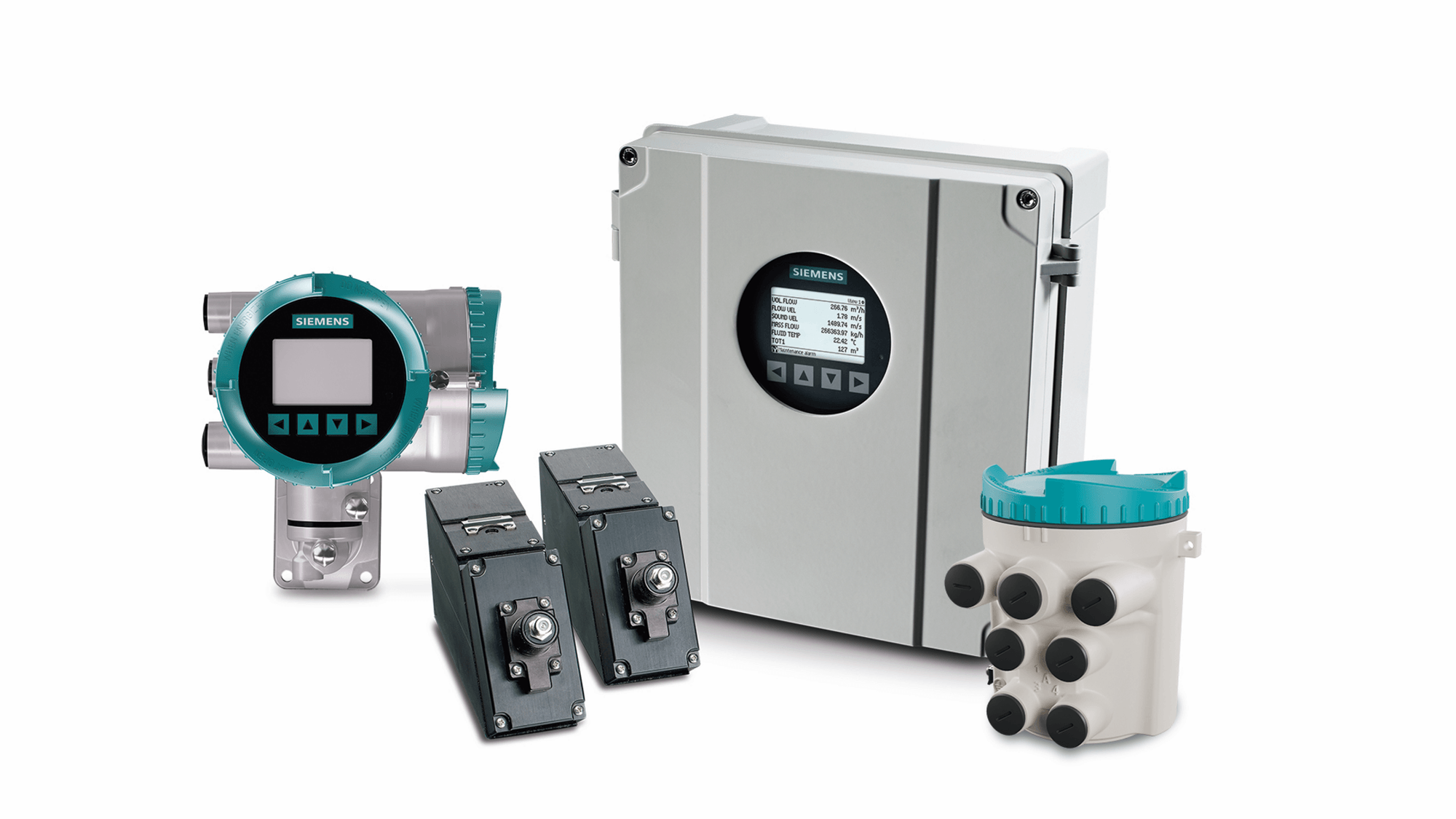

Flöde SITRANS F

Elektromagnetisk, Coriolis, Ultraljud, Vortex, Differenstryck

Mät flödet av vätskor, gaser och ånga med större tillförlitlighet. Den betrodda SITRANS F produktfamiljen har mångsidiga och tillförlitliga mätlösningar byggda för att passa alla branscher och processer, från enkla flödesindikatorer till avancerade, busskompatibla elektroniska system.